Please Contact us to Receive an Instant Quotation

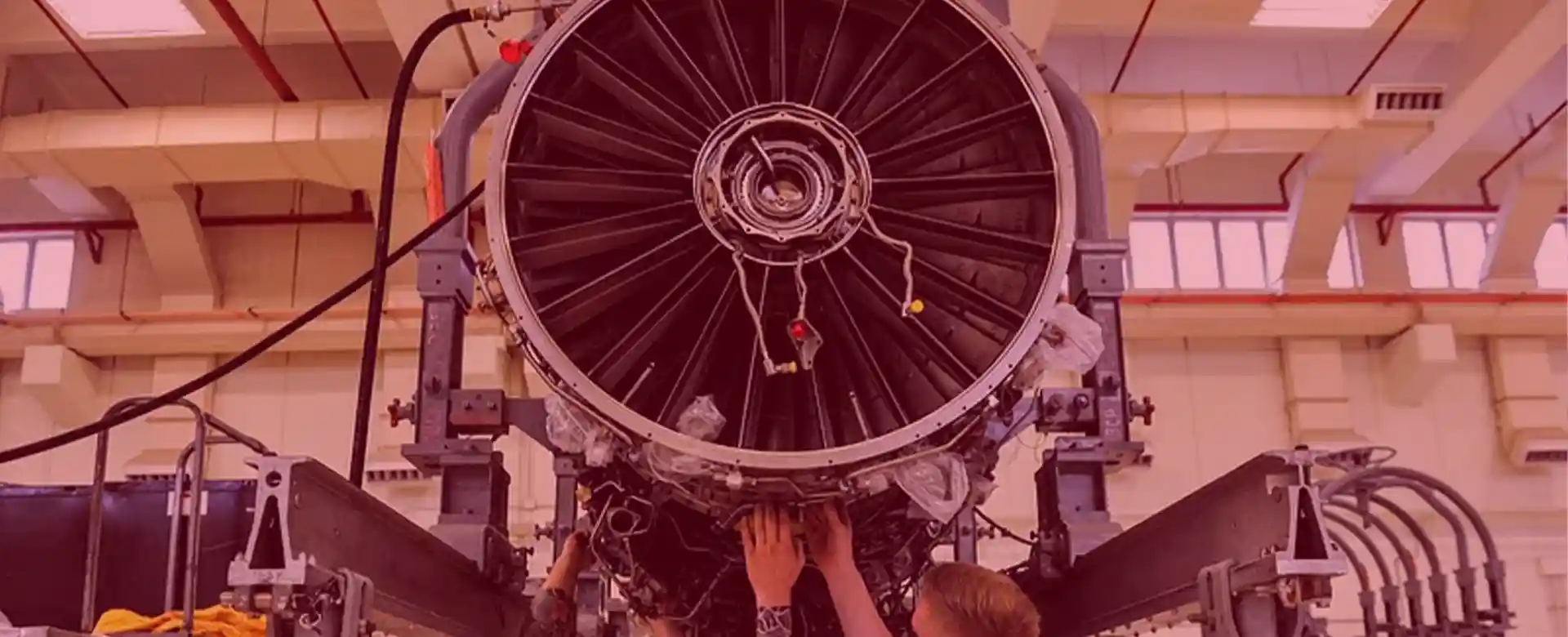

Warrantied inventory at

competitive prices

Search the world’s largest inventory of civil aviation components by manufacturer, category, or part number

We sell only warrantied

and traceable parts

All inventory ready to ship

from our sellers

The only independent

The only independent

“We Proudly Support Intrepid Fallen Heroes Fund that serves United States Military Personal experiencing the Invisible Wounds of War : Traumatic Brain Injury (TBI) and Post Traumatic Stress (PTS). Please visit website (www.fallenheroesfund.org) and help in their valiant effort”.

We Hope that You Will Visit Us Again the Next Time You Need Aircraft Parts and Make Us Your Strategic Purchasing Partner.

Request for Quote