Piston helicopters are powered by piston engines in either a single-engined, twin-engined, or four-engined configuration. Piston (also called reciprocating) engines and turbine engines are the most common powerplants available on helicopters. Piston engines in particular were one of the first types of engines utilized on helicopters once internal combustion technology became viable in the late 19th century. Reciprocating engines are now being increasingly replaced by lightweight turboshaft engines, however, which provide greater power and more flight hours alongside a low weight penalty. Despite this, piston engines retain popularity on light helicopters whereas turbine engines dominate larger and military helicopters. Reciprocating engines are used primarily on smaller helicopters such as light utility transports and trainers due to their simplicity, fuel economy, and relative inexpensiveness compared to turbines (which can go for ten times the cost).

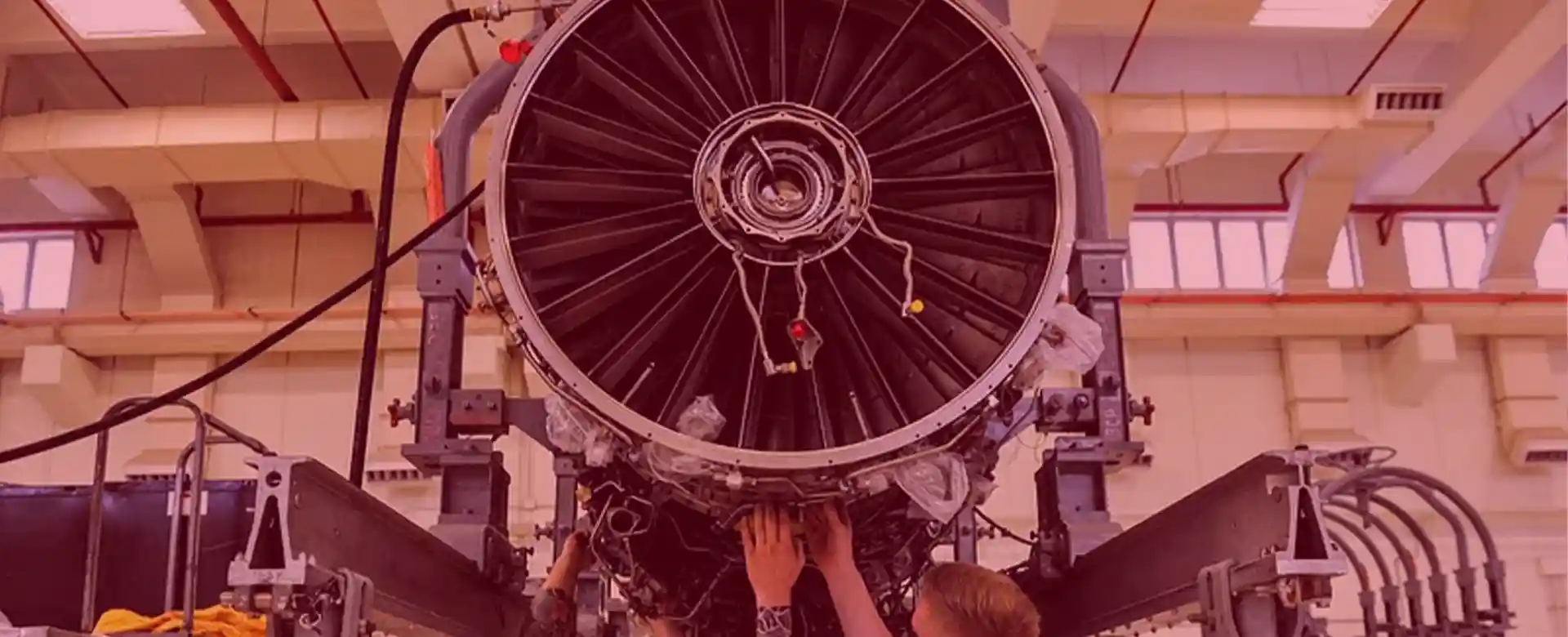

Piston engines consist of moving pistons which are contained in cylinders, and the up-down movement of operations serves to rotate an attached crankshaft. This crankshaft, in turn, powers the helicopter rotor. Piston engines are typically mounted on the aircraft in either a horizontal or vertical arrangement, with power transmitted to the vertical main rotor shaft. The most common reciprocating design is the four-stroke engine which undergoes a four-stroke cycle process to generate power: intake (wherein air is ingested towards the combustion chamber), compression (during which fuel and air are compressed), power (when spark plugs ignite the air/fuel mixture and expanding gasses trigger the power stroke, rotating the crankshaft), and lastly exhaust (the piston stroke expels burned gasses through an exit valve). This cycle is undertaken several hundred times per minute with each cylinder (in a four cylinder engine) carrying out a different stroke.

Unlike turbine helicopters, which have minimal rotor load, piston helicopters require a clutch to manage load from the rotor system, disconnecting the engine and enabling a motor to turn and start the engine. Piston helicopters use three types: the centrifugal clutch, belt clutch, and sprag clutch. Piston helicopters also use a different fuel control system – the carburetor or fuel injection system – whereas turbines can use FADEC (electronic control) or mechanical units. Additionally, a piston helicopter’s power control indications are displayed on the manifold pressure gauge whereas turbine engine helicopters see power on the torque gauge.

Please Contact us to Receive an Instant Quotation

Warrantied inventory at

competitive prices

Search the world’s largest inventory of civil aviation components by manufacturer, category, or part number

We sell only warrantied

and traceable parts

All inventory ready to ship

from our sellers

The only independent

The only independent

“We Proudly Support Intrepid Fallen Heroes Fund that serves United States Military Personal experiencing the Invisible Wounds of War : Traumatic Brain Injury (TBI) and Post Traumatic Stress (PTS). Please visit website (www.fallenheroesfund.org) and help in their valiant effort”.

We Hope that You Will Visit Us Again the Next Time You Need Aircraft Parts and Make Us Your Strategic Purchasing Partner.

Request for Quote